Shelving with flare

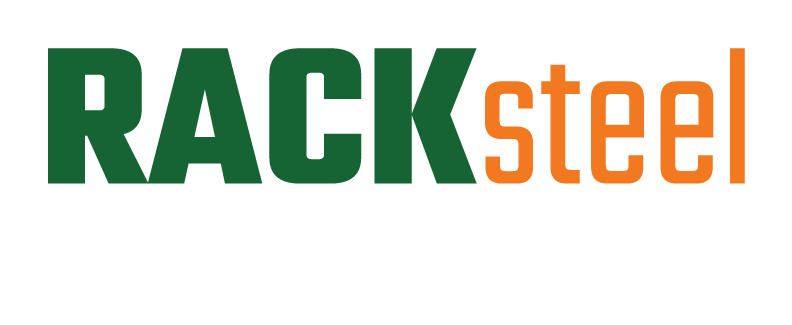

Carton Flow Racking: Gravity-Fed System for Fast Order Picking

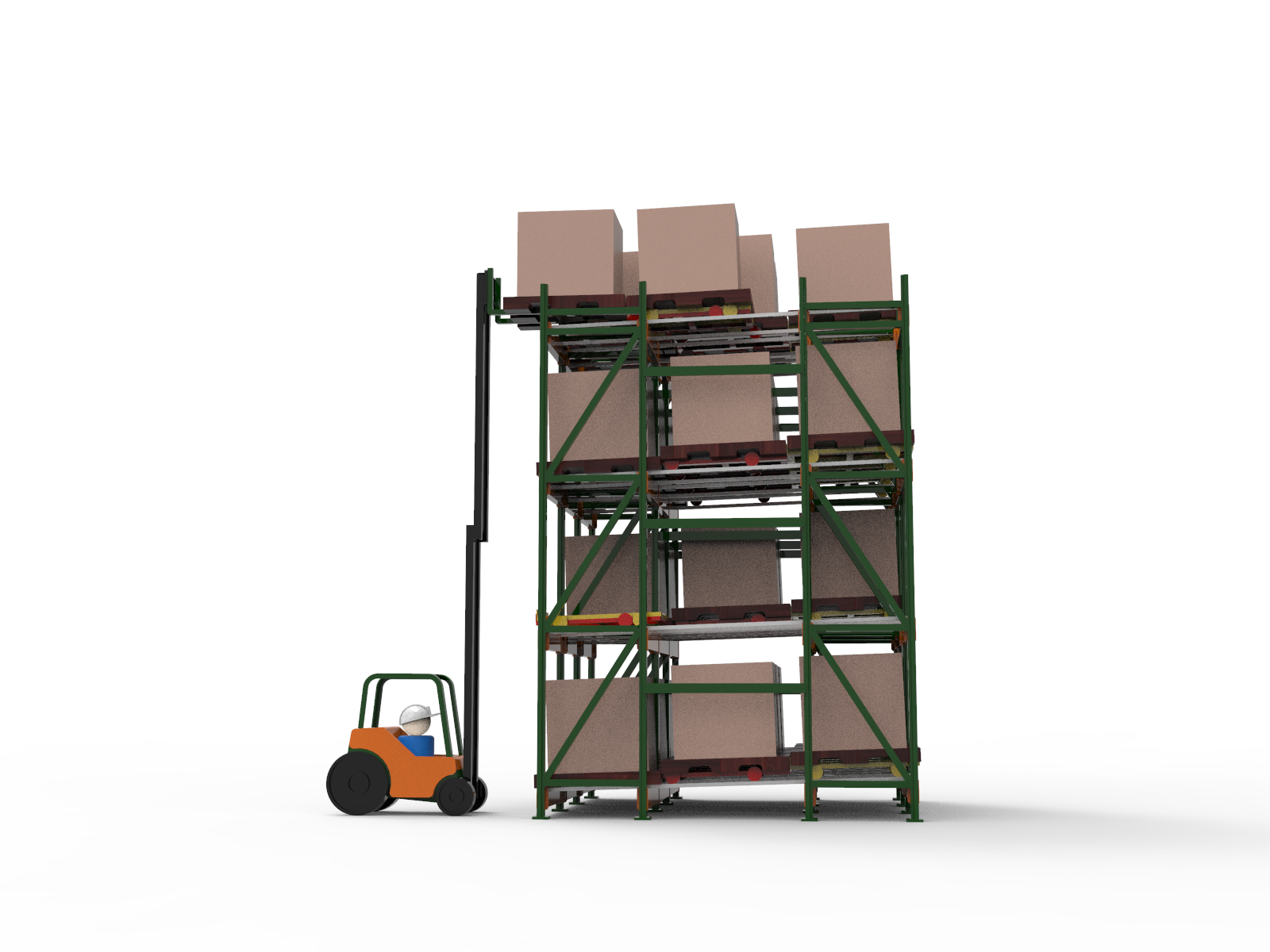

Carton flow racking uses inclined roller tracks to create a gravity-fed system for cartons and small inventory items. This system enables efficient stock rotation and rapid order picking, making it ideal for high-turnover environments such as e-commerce fulfillment centers. Carton flow racking supports FIFO inventory management, ensuring accurate stock rotation while improving picking accuracy. This racking solution is particularly effective in operations with high SKU variety and dynamic order fulfillment needs

When RACKsteel Recommends Carton Flow Racking

Carton flow racking is ideal for businesses with high SKU variety and rapid picking needs, such as e-commerce, pharmaceuticals, and automotive parts. RACKsteel’s team conducts a detailed analysis of your picking processes and throughput to ensure this system meets your operational demands.

Specific Benefits:

- Optimized FIFO Rotation: Ensures that older inventory is picked first, reducing waste in perishable goods.

- Improved Picking Speed: Gravity moves items to the picking face, reducing operator travel time.

- Compact Design: Maximizes the number of SKUs accessible from a single aisle.

Specific Limitations:

- Limited to Small Items: Designed for cartons and boxes rather than palletized goods.

- Maintenance Intensive: Roller tracks need regular cleaning and inspections to avoid downtime.

- Higher Initial Costs: More expensive than standard shelving due to the complexity of the track system.

Installation and Engineering

With our specialized factory partners, RACKsteel delivers carton flow racking systems engineered for durability and efficiency. Our installation experts ensure seamless integration with your warehouse operations.

Testimonials